Miura Golf

@MiuraGolfIncOfficial account of Miura Golf. Makers of the world's finest forged golf clubs. #DiscoverPerfection

Similar User

@odysseygolf

@truetempergolf

@BettinardiGolf

@ACCRAGolfShafts

@bridgestonegolf

@KBSGolfShafts

@golfpridegrips

@ProjectXGolf

@MizunoGolfNA

@cobragolf

@SuperStrokeGolf

@PingTour

@GolfWRX

@TrackmanGolf

@SrixonGolf

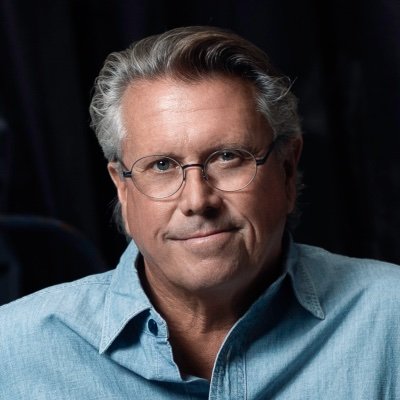

Adam Scott visits the Miura Factory in Himeji, Japan! Watch the documentary of his behind the scenes tour and insight into the new AS-1 irons: youtu.be/tdvyg7NySLA

The final step in the polishing process involves filling the club head, which includes painting logos, numbers, and colors on each product

Crafted with the precision and artistry of a samurai swordsman, the (剣士) Divot Repair Tool is a testament to exceptional craftsmanship. miuragolf.com/products/kensh…

The PI-401 combines the renowned Miura “feel” with performance enhancing technology, enabling the golfer to get the most out of their game.

The movement and vibrations of the dynamic polishing machine polishes the club heads to a degree that is unachievable by hand. Each club spends eight hours in the barrel in order to achieve the best result.

Forged in Himeji, Japan A feel like no other Katsuhiro Miura set out to make something elegant and refined, to create something beautiful, with the highest degree of integrity

The TC-201 combines muscle back performance with cavity back forgiveness Build yours today at miuragolf.com

Shaping is the most important step in the grinding process. It is responsible for the seamless transition from short to long irons. Each iron has its own build, and there are many components that go into shaping a particular iron.

IC-602; Miura tradition with modern manufacturing technology

The unique shape and weight distribution on the back of the KM-700 club head optimizes the center of gravity position for each iron. This revolutionary club head design, seen most notably with the toe grind, also promotes a return to square at impact, benefitting all golfers

The face grind is done with a machine that adjusts the depth and grooves. During this process, the Miura craftsmen ensure the groove shape and subsequent performance specs are produced to meet the R&A and USGA requirements.

Looking to add RAW wedges to your bag? The Forged Y and C Grind Wedges are now available in RAW. Grab yours today at miuragolf.com!

The new Forged Y and C Grind Wedges are now available in Raw Finish! Grab yours now at miuragolf.com/collections/fo…

United States Trends

- 1. $MAYO 9.781 posts

- 2. $CUTO 7.453 posts

- 3. Tyson 376 B posts

- 4. Pence 42,3 B posts

- 5. Laken Riley 34,1 B posts

- 6. Dora 21,9 B posts

- 7. Ticketmaster 15,8 B posts

- 8. Mike Rogers 5.919 posts

- 9. Cenk 9.223 posts

- 10. Mr. Mayonnaise 1.341 posts

- 11. #FursuitFriday 15,1 B posts

- 12. Pirates 17,8 B posts

- 13. Kash 66,6 B posts

- 14. The UK 430 B posts

- 15. Iron Mike 15,4 B posts

- 16. DeFi 106 B posts

- 17. Scholars 10,7 B posts

- 18. #LetsBONK 3.629 posts

- 19. Al Gore 3.102 posts

- 20. Oscars 13,6 B posts

Who to follow

-

Odyssey Golf

Odyssey Golf

@odysseygolf -

True Temper Golf

True Temper Golf

@truetempergolf -

Bettinardi Golf

Bettinardi Golf

@BettinardiGolf -

ACCRA Golf Shafts

ACCRA Golf Shafts

@ACCRAGolfShafts -

Bridgestone Golf

Bridgestone Golf

@bridgestonegolf -

KBS Golf Shafts

KBS Golf Shafts

@KBSGolfShafts -

Golf Pride

Golf Pride

@golfpridegrips -

Project X Golf

Project X Golf

@ProjectXGolf -

mizunogolf

mizunogolf

@MizunoGolfNA -

COBRA Golf

COBRA Golf

@cobragolf -

SuperStroke

SuperStroke

@SuperStrokeGolf -

PING GOLF

PING GOLF

@PingTour -

GolfWRX

GolfWRX

@GolfWRX -

Trackman Golf

Trackman Golf

@TrackmanGolf -

Srixon

Srixon

@SrixonGolf

Something went wrong.

Something went wrong.